ApexRay HD 3D Crystal Subsurface Laser Engraving Machine

Contains

1. A UV subsurface laser engraving machine for HD 3D/2D engraving in crystal and glass, plus all standard 5W UV laser functions (Like surface marking on plastic, silicone, wood, leather, stone, metal, etc.).

2. Extended 2-year warranty with free repairs/replacements

Lifetime technical support

Free global doorstep delivery

Comprehensive training package

Rock-Solid ApexRay HD UV Laser Subsurface Engraving Machine

The ApexRay is an advanced HD UV laser All-in-one engraving machine designed for precision 3D engraving within transparent materials such as crystal and glass. Its state-of-the-art UV laser technology brings intricate 3D designs to life inside the material without affecting the surface.

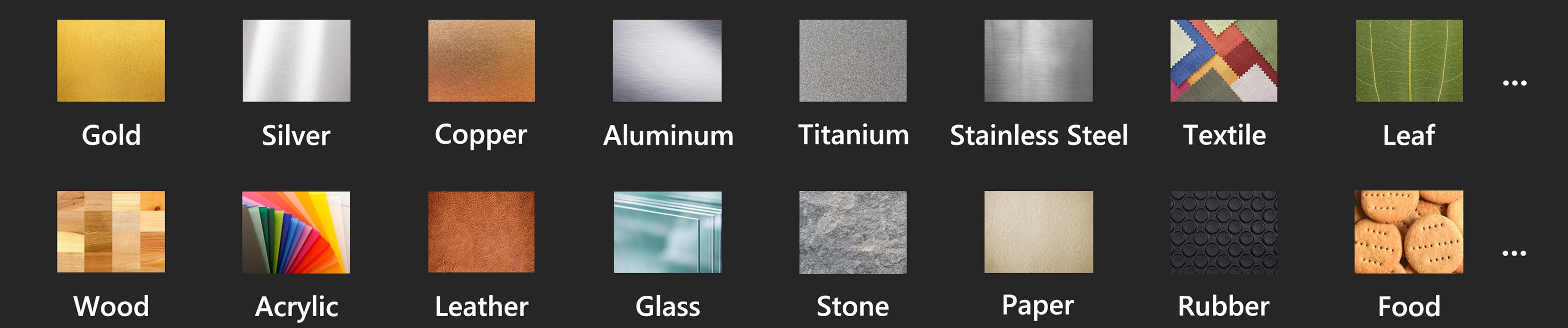

In addition to subsurface engraving, the ApexRay is highly versatile, capable of precise surface marking on a wide range of materials, including plastic, metal, wood, paper, leather, leaves, and acrylic. This makes it an all-in-one solution for creating customized gifts, awards, decorative items, promotional products, and more, combining professional-level precision with broad material compatibility

Key Use Cases

Common applications include creating high-end awards, personalized gifts, home décor, and intricate glass artwork. Our UV laser machine offers versatility beyond 3D subsurface engraving, enabling 2D surface marking on various materials like plastic, wood, leather, and silicone.

Crystal Awards & Trophies

Ideal for luxury 3D-engraved recognition pieces.

Home & Corporate Décor

tunning internal engravings on glass for both personal and professional settings.

Souvenirs & Gifts

Create personalized 3D designs inside glass for memorable keepsakes.

Applications & Working Principles

This machine uses UV laser technology to create tiny fractures or "bubbles" inside transparent materials. By carefully focusing the laser at precise coordinates, these fractures come together to form detailed 3D images and patterns within the material, creating a floating effect.

Why Choose Our Machine?

Exquisitely detailed

ApexRay 3D Crystal Laser Engraving Machine features advanced UV laser technology with an ultra-fine spot size—significantly smaller than traditional green lasers used by most competitors. This enables the ApexRay to capture exceptionally intricate details and deliver crystal-clear results, even in miniature designs.

Industrial-grade High Performance & Stability

The core components of the machine use industry-leading products, ensuring excellent performance and stable quality. Both water-cooled and air-cooled models offer ultra-high precision and an extended service life. The specially optimized optical system ensures that 3D engravings inside the glass are uniform, complete, and free from distortion.

Wider Application

Beyond 3D subsurface engraving, the ApexRay also supports precise surface marking on a wide range of materials — including plastic, glass, wood, leather, paper, and silicone. This versatility makes it an all-in-one solution for both artistic creations and industrial applications.

Compact Design,

Industrial Performance

ApexRay features a compact, desktop-sized design that fits easily into any workspace. Despite its small footprint, it delivers industrial-grade precision and durability, ensuring professional-quality results for every engraving. With its easy setup and stable performance, the ApexRay is ideal for studios, workshops, retail stores, and on-site customization events.

Affordable Excellence

Despite its advanced capabilities, ApexRay is offered at only 1/3 to 1/2 the price of most laser subsurface engraving machines on the market—delivering exceptional value without compromising performance or quality.

What You Will Get?

1. A UV subsurface laser engraving machine for HD 3D/2D engraving in crystal and glass, plus all standard 5W UV laser functions (Like surface marking on plastic, silicone, wood, leather, stone, metal, etc.).

With Premium Components

- UV laser source by Advanced Optowave (a leading US brand, 20,000+ hours lifespan)

- High-end optical system (2-3x the cost of standard optics) – precision-tuned for flawless crystal engraving.

- Industrial motorized lifting system – features reinforced structural design and high-grade transmission components, delivering exceptional engraving precision and durability far beyond standard systems (3-4x higher investment than conventional solutions).

- Constant-temperature water chiller (For water-cooled model) – ensures stable laser performance.

- Professional 2D/3D engraving software (subsurface & surface compatibility).

- 1–2 interchangeable lenses (50×50mm & 70×70mm). Note: Smaller lenses (50×50mm) deliver finer detail. Choose based on needs, or select both for flexibility. Optional lenses support up to 175×175mm 2D engraving area.

2. Exclusive Value-Added Services

- Extended 2-year warranty with free repairs/replacements

- Lifetime technical support

- Free global doorstep delivery

- Comprehensive training package:

Detailed user manuals

Step-by-step video tutorials

Online operation guidance - Regulatory compliance: Full CE/FDA certification documents

- Raw crystal glass material sourcing: available at factory prices (shape/size tailored to your designs).

- Massive 3D design library: Instant access to thousands of ready-to-use 3D graphic files for fast download

- Software update services: Update the software from time to time to add new features and fix minor problems.

Specification

| Model Number | RSD-UV3DSE-W | RSD-UV3DSE-A |

| Laser Source | Advanced Optowave® 5W UV Laser Water-cooled |

Advanced Optowave® 5W UV Laser Air-cooled |

| Wavelength | 355nm | |

| 3D Subsurface Engraving Area | 50*50*100mm (with 50*50mm lens) 70*70*150mm (with 70*70mm lens) |

|

| 2D Surface Engraving Area | Up to 175*175mm (lens-dependent) | |

| Applicable Material (Subsurface Engraving) |

K9 Glass / Crystal | |

| Applicable Material (Surface Engraving) |

Plastics, Glass, Crystal, Wood, Leather, Metal, Fabric, Stone etc. | |

| Z-Axis Control | High precision screw-lift column with a braking stepper motor for high accuracy, controlled by the software | |

| Input Voltage | 100-230V / 50-60Hz | |

| Laser Control Board | RKCAD | |

| Software | RKCAD with subsurface engraving function | |

| Supported File Format | 3D: STL, OBJ Vector: AI, PLT, DXF, JWW, DWG Image: Grey scale depth map, BMP, JPG,GIF, PNG, ICO, ICNS, SVG, TGA, TIFF, WBMP, WEBP, XBM |

|

| Supported O/S | Windows 11/10/7 32/64bit | |

| Minimum Computer Hardware Requirement | Intel i5 7th generation or above, 16GB RAM or higher, 2GB Graphics Card or higher (Graphic card must support DX12/OpenGL Version 2.1). | |

| Laser Beam Quality (㎡) | <1.1 | |

| Max. Subsurface Engraving Speed | 6000 points/s | |

| Max. Surface Marking Speed | 3000 mm/s | |

| Repeatability | ±0.001mm | |

| Power Consumption | 800W | 500W |

| Cooling System | Water Cooling | Air Cooling |

| Environment Temperature | -5~45℃ (23~113℉) | -5~35℃ (23~95℉) |

| Machine Weight (Include water chiller) | 45kg | 32kg |

| Gross Weight | 55kg | 42kg |

| Package Size | 68*42*71cm | 68*42*71cm |

Engraving Speed

The processing time depends on the size and complexity of the 3D design, as well as factors such as dot density and laser parameter settings. For example, engraving a glass cube measuring 80 × 50 × 50 mm typically takes 10 to 30 minutes

We have an extensive collection of successful case studies

Feel free to contact us for more details.

We can also create customized samples tailored to your specific needs.

Optional Spare Parts

F-theta lenses

50×50mm, 70×70mm for 2D and 3D engraving

70×70mm, 110*110mm, 150*150mm, 175*175mm for 2D engraving

Note: Smaller lenses (smaller engraving areas) provide finer quality. Please choose the lens that fits your needs.

Differences Between Air Cooled & Water Cooled Model

The performance is exactly same. The difference is working environment temperature requirements. The air-cooled model operates within a temperature range of -5 to 35°C (23~95℉), while the water-cooled model can function in temperatures from -5 to 45°C (23~113℉). The water-cooled model is better suited for hotter climates and offers more stable performance in high-temperature environments. If your workplace is typically hot, we recommend choosing the water-cooled model. On the other hand, the air-cooled laser eliminates the need for a water chiller, offering advantages such as simpler installation and maintenance, lower noise, smaller size, lighter weight, and easier transportation.

Contact Us to Learn More

Ready to take your engraving projects to the next level? Contact us today for more information on our HD laser subsurface engraving machines and how they can transform your business. Our team is here to answer your questions and provide expert guidance.